It is also known as plastic strain or stain applied beyond the yield strength limit of a material. Percent elongation represents the ability of the material to be plastically deformed under tension. The Deformation of Clad Aluminum Sheet Produced By Direct Chill Casting – Scientific Figure on ResearchGate. We can use them to learn which alloys have better baseline formability.

We can use these tests to establish a formability “ranking” for different sheets of alloy. That said, there are standardized tests, such as the ASTM E2218: Standard Test Method for Determining Forming Limit Curves. However, changing the shape of the part or the physical properties of the starting material will change the amount of force that needs to be applied. In other words, we can measure the forming force to produce a specific part from a particular starting material. It also depends on factors such as the shape of the part and the thickness of the starting material. For example, the applied force necessary to shape a product depends on more than just the strength and ductility of a material. Generally speaking, formability is a relative term and not a specific value. Permanent deformation is also known as plastic deformation in the materials science world.

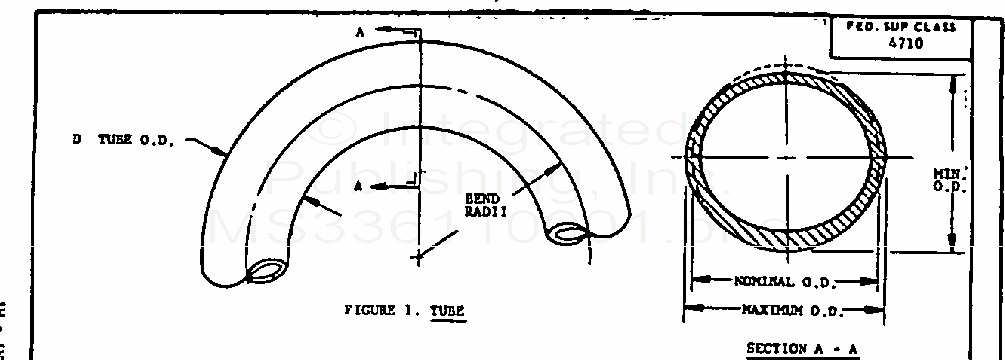

Not all sizes are available off-the-shelf and some sizes will be available only as mill orders. Most tubes are available in stock lengths while some of the smaller round sizes may also be furnished coiled in longer lengths. The following table presents some common tubing sizes for round, rectangular, and square profiles. Some rectangular shapes are available with radiused corners. It is specified by outside diameter and wall thickness or inside diameter, or, by stub gauge, for round tubing, and by leg length and wall thickness for rectangular tubing. Aluminum tubing is drawn or extruded and is available as round and rectangular shapes.

0 kommentar(er)

0 kommentar(er)